It’s not often that I’ll agree to doing a 10-5 day on a Saturday. However, when it involves the chance to make my own cider, I can be persuaded…

With their first anniversary rapidly approaching (they first opened their doors in December 2010), the Bristol Cider Shop have had a whirlwind year. In addition to the shop, which sells a range of ciders, perries, brandies and aperitifs produced within 50 miles of Bristol, they’ve now turned their hand to events. With markets, cider dinners with the Bishopston Supper Club and a presence at various festivals under their belt, my friend Nick (author of The Cider Blog) and I were lucky enough to join six other cider enthusiasts on the shop’s first ever Cider Making Day.

Starting at the shop on the Christmas Steps at 10am, we were fortified with a cuppa and a shot of Somerset cider brandy (which has recently gained PGI status) before being chauffeur driven to our first destination: visiting cider-maker Mark Catlin at Lyne Down Cider & Perry, on the edge of the Marcle Ridge in South Herefordshire.

Here we were to learn about traditional cider making methods, using a range of apple varieties from Lyne Down’s orchard and surprisingly small-scale equipment for a company whose cider is available commercially.

Our first task was picking the apples – armed with buckets and sacks and accompanied by Mark’s very enthusiastic puppy Jack, we headed into the orchard…

Here we selected only apples that had already fallen to the ground, discarding those that were rotting and shaking the branches of the trees once we had used up those already on the ground.

Heading back to the barn, Mark put all of the apples – around 5 different varieties – through the scratter to chop them into small pieces, ready to press.

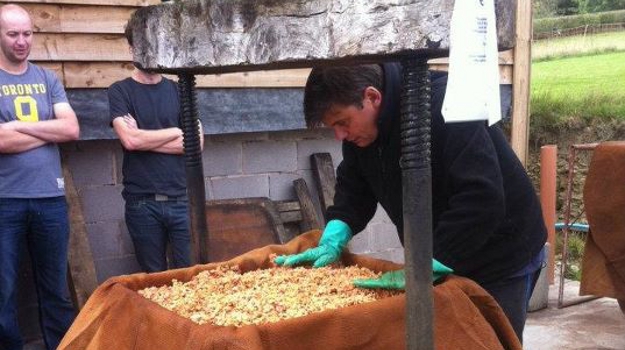

Lyne Down’s traditional antique stone twinscrew press is around 120 years old, but still does the job! After placing a cheesecloth in the square frame, we filled it with apple and folded the edges over before repeating, ending up with 12 or 13 cloths stacked on top of each other before tightening the press.

While the juice was pressing, we headed into the barn, which houses the fermentation vats where the magic happens.

Mark bottled up our apple juice from the press – we were given a gallon each in containers with special fermentation caps…apparently if we leave these for 3-4 weeks in a dark and warm place, they’ll turn into cider…

Leaving Mark hard at work, we stayed in the barn and took the opportunity to sample five of his ciders: single variety Browns and Kingston Black, an oak cask medium sweet cider, Roaring Meg – made with a variety of cider apples and named after one of Cromwell’s cannons, and an only recently produced mulled variety. It was the Browns that won my vote, and Nick and I bought three bottles between us to take home. After a quick lunch, we loaded up the people carrier with our purchases, our juice and a bottle of apple and blackcurrant juice that Mark had given each of us, and got back on the road for the second half of our day – a tour of Westons Cider.

From a small, local producer to a large international one: the sheer scale of Westons is unbelievable. The company’s humble beginnings in 1880, when farmer Henry Weston used to make cider as a hobby, are long gone – although a traditional millstone and later hydraulic press are on display to the public, it’s industrial machinery that is now responsible for everything, even down to the three different machines that they use to harvest the apples.

Producing around 6 millions gallons of cider in the last year alone, and exporting to over 30 countries around the world, the Westons production system is a world away from that of Lyne Down. Around 130 different varieties of apple are used to make their ciders, and the size of just one of their apple pits clearly highlighted the differences in scale.

The sheer quantities involved mean that cider making is a year-round process, with all of their products being stored as a base cider in 200,000 litre stainless steel vats.

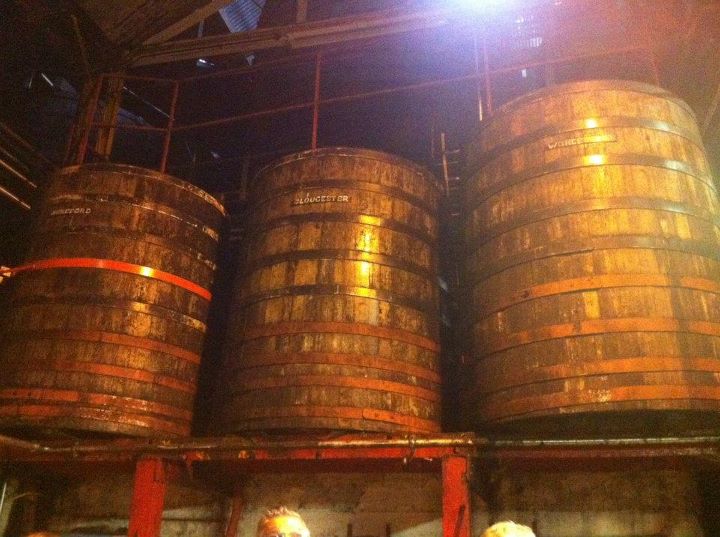

Despite the commerciality, though, it’s good to see that a touch of personality still runs through the process, with the company’s fermentation casks (the largest holding 42,107 gallons of cider!) all named after things and people that Henry Weston held dear: his daughter, his favourite football teams and cartoon characters, and (in the picture below) the three cities in which he grew up.

After the tour, it was on to the Westons shop to taste their products, the collection of our free Stowford Press pint glass, and back in the people carrier, taking the scenic route back to Bristol, where we reconvened at the Bristol Cider Shop for a bit of a tasting session before heading home.

A truly fantastic day: it was fascinating to learn how different the methods of cider production are depending on the scale of a producer – and probably a bit of a wake-up call for cider drinkers who aren’t acquainted with the smaller producers. We all had a lot of fun getting stuck in with the whole process at Lyne Down, and it’ll be interesting to see how our cider turns out! Many thanks to Bristol Cider Shop for an incredibly eye-opening and educational day.

Bristol Cider Shop have another cider making day scheduled for Sunday, October 16th. There are only a few places still available – click here for more details…

Find Bristol Cider Shop on the Bristol Bites Directory…

[mappress mapid=”15″]

Was a really fun day. Fingers crossed my cider ferments well 🙂

What a wonderful day, my idea of a great day out, did you find someone to drive you home so you could have a decent taste?

cheers

marcus

It was fantastic! The cost of the day included transport to and from the venues…so not only did we have a lift, but plenty of storage space for our purchases! 🙂